Energy Solutions

United Filters International manufactures energy solutions from petroleum, to gas, to process fluids.

United Filters International has continually served the filtration needs of the Gas and Petrochemical lndustry for over 30 years. UFl’s warehouse is ideally located in Amarillo, Texas, with an extensive inventory ready to support those critical times when rapid turnaround is needed for those unpredictable “upsets”.

UFl’s filters are manufactured from both natural and man-made media’s which include but are not limited to: cotton, nylon, fiberglass, rayon and polypropylene materials (see string wound section). Clay and Zeolite filled cartridges are also available. Cores and end caps are matched to interface with new or existing vessels. These caps and cores are manufactured using polymer or various metals to meet the needs of our customers.

UFI Dual Wind Cartridges

UFI Dual Wind Cartridges are particularly suitable when the contaminants within the liquid cover a broad range of particle sizes. The more open outer winding traps the larger particles while the tighter internal wind captures the smaller, fine micron particles.

This dual wind filter cartridge provides longer cartridge life without altering the efficiency of the filter element. Several field applications involving Dual Wind elements have similarly resulted in three times the normal filter life with equal or superior efficiency over single micron rated elements. Dual Wind elements are available in various media, core, end cap and micron ratings to meet your specific requirements.

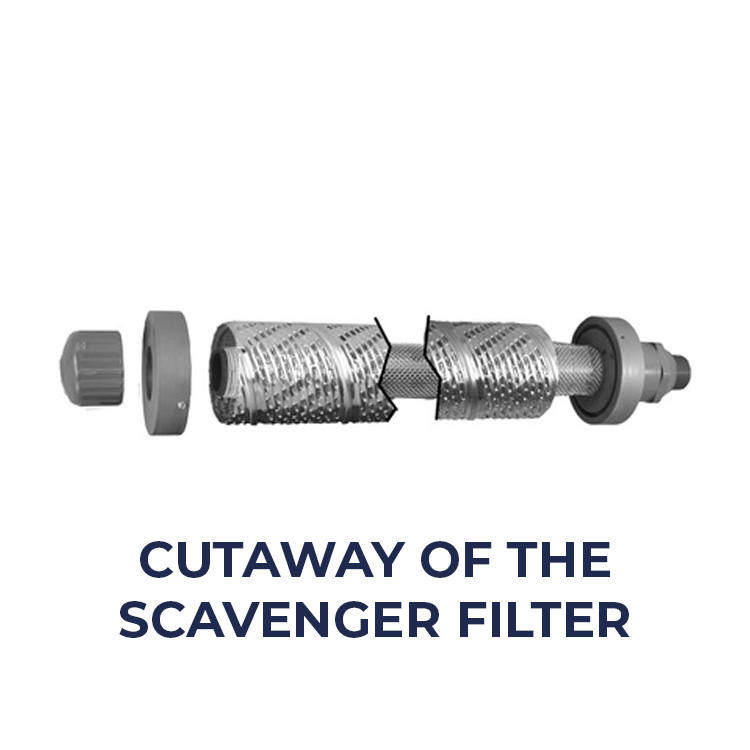

UFI Stainless Steel "Scavenger" Filters

UFI Stainless Steel "Scavenger" Filters are specified for high contaminant load particularly suited for the oil industry. Features of the Scavenger Filter:

- Available in 18 to 72-inch lengths

- Double open ended/Buna available

- 150 psi differential operating pressure

- Available in 20 to 250-micron nominal micron ratings

- Housing interface of .5-inch, .75-inch and 1.0-inch NPT/DOE

- No tools required for field cleaning and parts replacement

- All stainless steel/PVC construction for fluid compatibility

- Cleanable without tools

The UFI "Rolled Sock Type" Filter Cartridge Series

The UFI "Rolled Sock Type" Filter Cartridge Series are high efficiency, outside to inside flow direction elements specifically designed for the removal of solid contaminants. They are manufactured using specific blends of media design for a range of applications in the oil and gas industry. The filter mat produced by the exclusive process provides a uniform gradient density filter media designed for long life and high particulate retention. The filter media is placed around a spiral locked metal core that provides superior support to resist high differential pressures witout collapse. The UFI “Sock” Fltration Series is one of the oldest, most economical, and most trusted filtration technologies in the oil and gas industry.

Specifications

- Standard micron rating: 2-125 μ

- Recommended initial DP: < 0.5 psid

- Recommended change-out DP: 15 psid

- Maximum temperature: 275° F

- Flow Direction: out to inside

- Configuration: open end

- Length: 36.5 inches

- Outside diameter: 3 inches

- Inside diameter: 1.6 inches

Materials

- Coalescing media: cotton, excelsior

- Outer sock: cotton, orlon, or polypropylene

- Center core: tinned steel, spiral locked

- Media carriers: cerex, remay, cheese cloth

- Double open ended with optional metal plug of SOE applications

- Gaskets: N/A

UFI Synthetic Pleated Polypropylene Series Filter Cartridges

The UFI Synthetic Pleated Polypropylene Series Filter Cartridges are pleated liquid filtration elements designed for applications with large flow and contaminant requirements. They have a range of efficiency, outside to inside flow direction elements specifically designed for the removal of solids contaminant in critical applications. The UPMP Polypropylene Filters are available in various grades of absolute rated high performance polypropylene media with hardware customizable to suit the application.

Specifications

- Standard micron rating: 10 µ

- Recommended initial DP: < 2.0 psid

- Recommended change-out DP: 15 psid

- Maximum temperature: 180° F

- Flow Direction: outside to inside

- Configuration: single open end

- Length: 36.56 inches

- Outside diameter: 6.55 inches

- Inside diameter: 1.75 inches

- Available in other sizes

Materials

- Media: polypropylene

- Core: tin-plated steel

- Outer cover: polypropylene

- End caps: nylon

- Gaskets: buna