String Wound Filters

United Filters International manufactures the highest quality in string wound filtration.

United Filters International String Wound Cartridge Filters provide true depth filtration, high dirt-holding capacity, and extremely low media migration. They are a superior, one-piece cartridge manufactured using a high speed continuous wind process

and are available in a wide variety of lengths and porosities.

Especially significant is the availability of filters in an almost endless combination of media and core material to handle virtually any chemical, environment, and/or temperature. U-Series String Cartridge Filters are available with fourteen string, seven core and twelve material and end cap options. Outside dimensions of 2 to 5 inches and lengths of 5 to 72 inches are standard. They can be sized for virtually all single-or multi-round filter housings.

The precise winding pattern defines micron ratings and results in higher dirt-holding capacity and efficiency. Our UPDN Series of polypropylene string cartridges are NSF/ANSI 42, 61, and 372 certified.

Types of String Wound Filters

Polypropylene

Available in three grades: standard grade for general filtration, FDA grade for potable water and liquids used for food and beverage applications, and NSF/ANSI 42/61 when certifiable material content and traceability of materials of construction are required. All polypropylene is compatible with most organic acids, alkalies, and chemical process applications. Very effective in low-viscosity solutions and easily incinerated to traces of ash. Excellent micro-organism resistance. For use up to 180 ºF.

Fibrillated Polypropylene

Non-migrating silt film polypropylene free of extractable or sizing agents. For use in ultra-pure, electronic, and plating applications where non-leaching is critical. Chemical resistance equal to standard polypropylene. Low moisture adsorption and outstanding abrasion resistance. Lowest static propensity of any man-made fiber. High dry or wet strength. For use up to 180 °F.

Cotton

Available in three grades: natural cotton for standard filtration applications, including oils, water, paints, organic solvents, alcohols and petroleum, bleached cotton that meets FDA Food and Beverage Standards for potable water, food and beverage applications, and industrial white cotton. Cotton has poor microorganism resistance. For use up to 300 °F.

Polyester

Chemical resistance similar to polypropylene, with higher temperature resistance. For use up to 350 °F.

Fiberglass

Available in standard grade for filtration of high concentrations of organic acids, organic solvents and petroleum solutions. Recommended for high temperatures and high-corrosion applications. For use up to 750 °F.

Rayon

Similar chemical compatibility to nylon and fiberglass. Fluid compatibility similar to bleached cotton, but with more coarse fibers and less absorption. Swells in aqueous solutions. Excellent resistance to solvents and acids with the exception of hot sulfuric and nitric acid. For use up to 300 °F.

Ryton

Ryton is resistant to acids, alkalies, and some solvents, even in extreme conditions. For use up to 375 °F.

Nylon

Used for special process applications, concentrated alkalies, and hydrocarbons. Excellent microorganism resistance. For use up to 300 °F.

Municipal String Filters (UPDN SERIES)

UFI’s UPDN Series cartridges have been tested and certified to NSF/ANSI 42/61/372 standards to ensure continuity of materials and consistency in manufacturing the finished product. Each component is identified and controlled in accordance with the registered wetted parts lists. These cartridges will not impart unwanted leached materials into the downstream flow.

UPDN Series cartridges offer a wide range of options suitable for most industry standard filter housings. Cartridges are double open-ended and range in size from 5 to 72 inches. Optional end cap treatments available (see End Treatments page in Resources section).

UPDN cartridges are in use at state and federal correctional institutions, office buildings, municipal water districts, Department of Defense road-mobile potable water systems, and other applications where NSF/ANSI 42/61/372 standards are required.

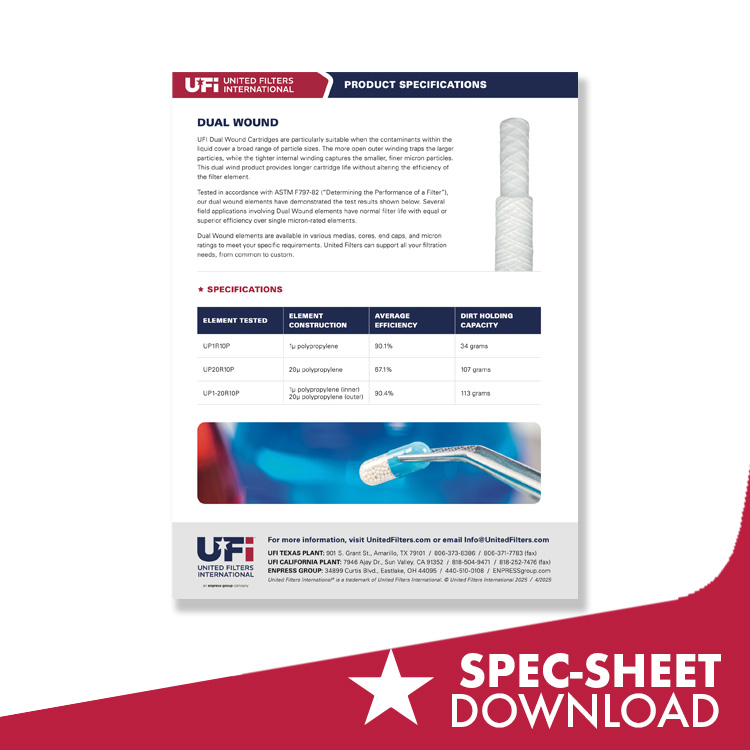

Dual Wound

UFI Dual Wound Cartridges are particularly suitable when the contaminants within the liquid cover a broad range of particle sizes. The more open outer winding traps the larger particles, while the tighter internal winding captures the smaller, finer micron particles. This dual wind product provides longer cartridge life without altering the efficiency of the filter element.

Tested in accordance with ASTM F797-82 (“Determining the Performance of a Filter”), our dual wound elements have demonstrated the test results shown below. Several field applications involving Dual Wound elements have normal filter life with equal or superior efficiency over single micron-rated elements.

Dual Wound elements are available in various medias, cores, end caps, and micron ratings to meet your specific requirements. United Filters can support all your filtration needs, from common to custom.

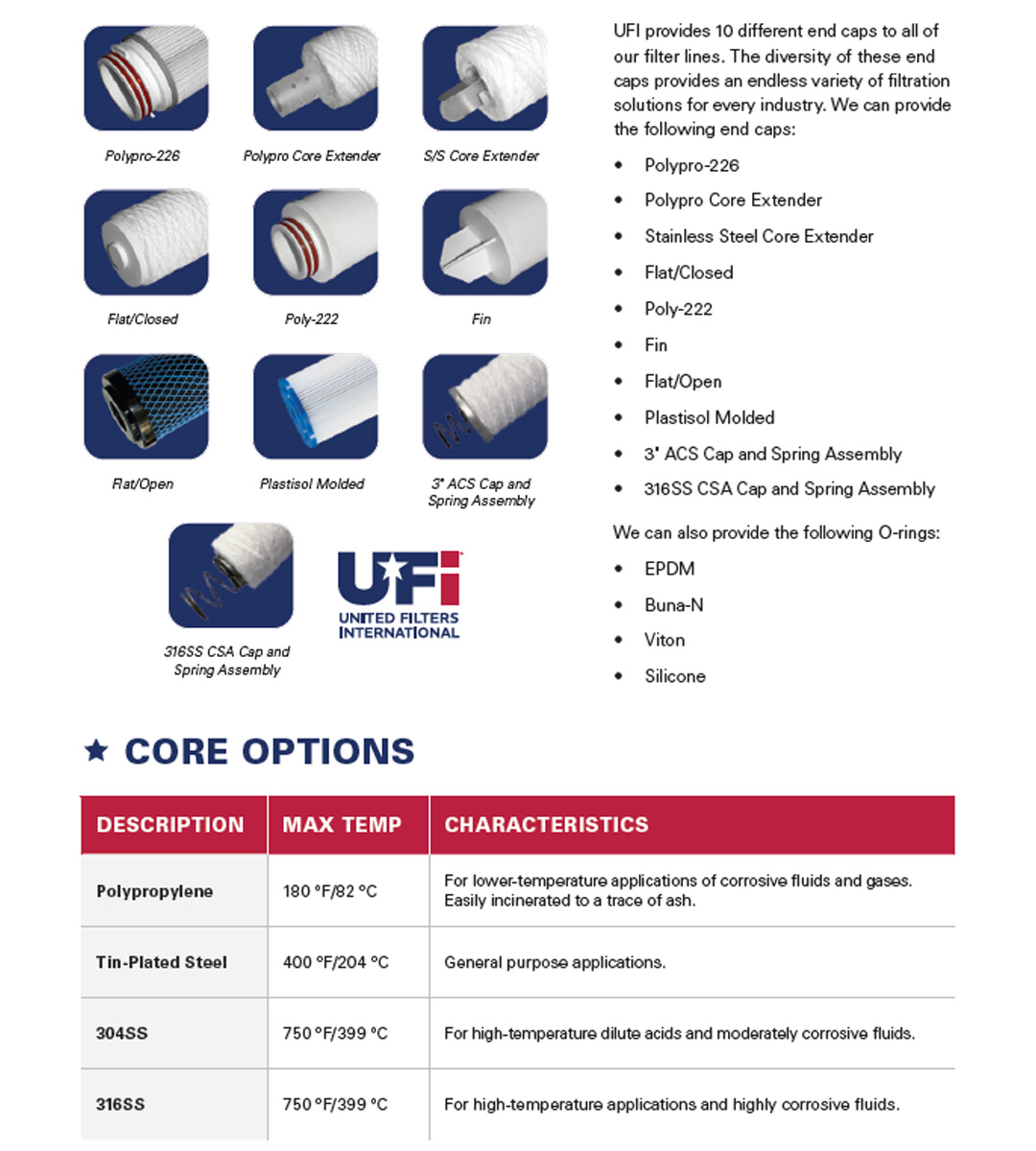

End Treatments